-

- ļīĆĒÖöņĀĢļ░ĆĻ│ĄņŚģņØĆ ņĄ£Ļ│Ā ĒÆłņ¦łņØś ņ×Éņ×¼ļź╝ ņāØņé░ĒĢśĻĖ░ ņ£äĒĢ┤ ļģĖļĀźĒĢ®ļŗłļŗż.

- Syringe Injection Method

Syringe injector

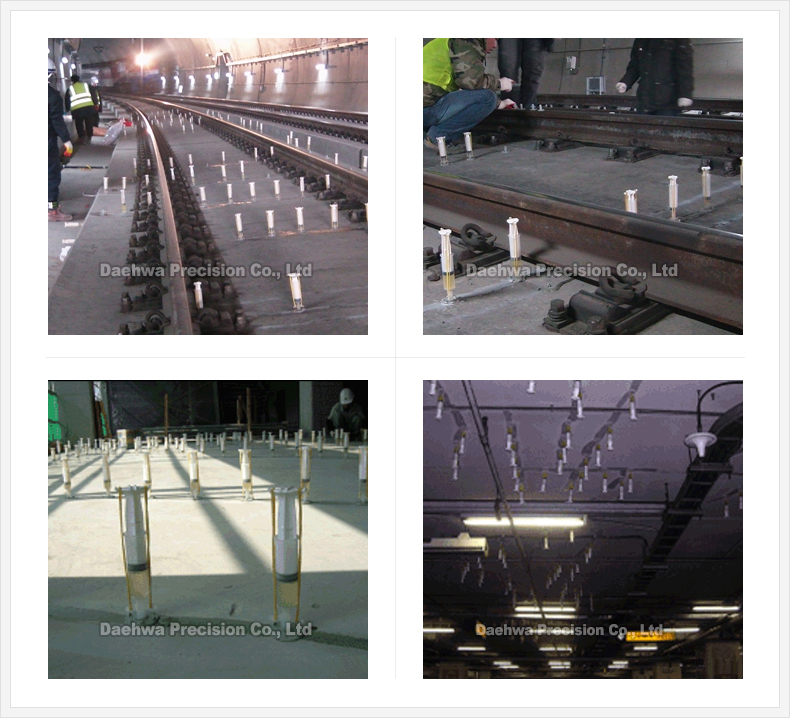

Automation equipment/caption> Automation equipment Grouting Method by Syringe Injector

This method enables the grouting material to infiltrate into the minute cracks by utilizing surface tension and capillary action of sucking up water without the supply of power. Most of conventional grouting methods use high pressure for injection, so the opposition pressure from the inside of the cracks often causes the breakage of sealing material and the leakage of grouting material, thus precluding the deep infiltration of the grouting material. However, grouting by syringe injector enables the perfect grouting of the cracks of concrete structures without any damage across a large area at the same time by injecting the grouting material slowly and continuously with low pressure.

-

Epoxy Injection (Syringe injector 3D) Epoxy Injection (Syringe injector 3D) -

Epoxy Injection (Syringe injector) Epoxy Injection (Syringe injector)

Characteristics

- You can inject unlimited amount of grouting material without bubbles (remove air) because you can apply pressure to the plural numbers of cracks sequentially or simultaneously.

-

2.Surface tension and capillary action can be fully utilized because of low speed injection and infiltration into the minute cracks or air void is possible thanks to the low pressure injection which employs the tensile strength of rubber bands.

As epoxy concrete is more than 4 times as strong as the base structure, it reinforces the weak parts around the cracks by eliminating or scattering the loads centered on, or moving to, the weakened parts if there is any threat to the safety of the structure. Namely, the spread or growth of early stage cracks can be prevented by reducing the local loads to the maximum by scattering the centered loads over a large area.

The best way for the water leakage (dampness) caused by cracks is to rework on the waterproofing but it involves an increased construction cost. And rework on the waterproofing with the cracks left unrepaired is most likely to lead to recurrence of defects. Because the waterproofing work on the parts that are not durable is meaningless, you have to choose a repairing method that can satisfy both durability and waterproofness. - Epoxy resin is the resin which is specially designed to have elasticity and receptivity against vibration or cracks and can be used for the syringe injection with a selection of viscosity and pot life.

Application Area

It can be applied to the following areas when the target member is the structural member and the measured width of cracks is larger than the tolerance, or when the structural stability, durability or waterproofing is sought for the cracks for over 0.1mm regardless of the identification of the structural member.- Repair and reinforcement of cracks in subway and tunnel.

- Repair and reinforcement of cracks of Pc plate, concrete molding product.

- Grouting reinforcement of aged or weakened parts of concrete.

- Repair and reinforcement of slab and upper plate etc.

- Grouting of loose gap of concrete plastering mortar and tile.

- Repair and reinforcement of bridge and bridge pier etc.

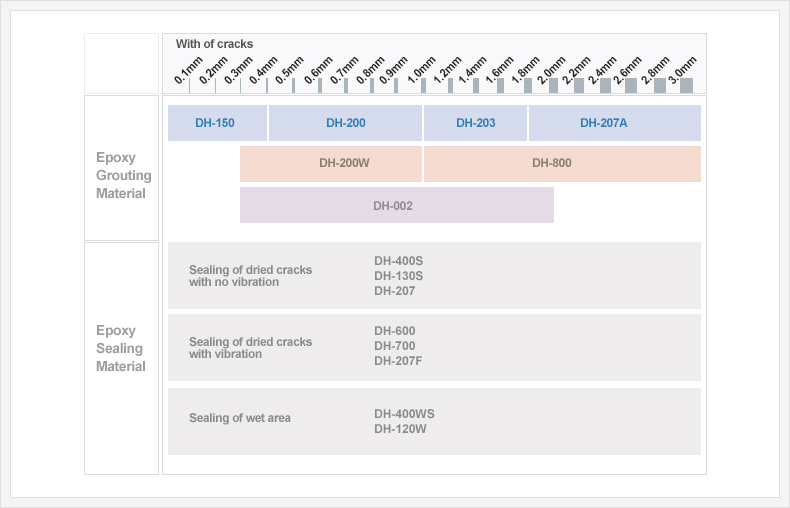

Materials of use based on the width of cracks

- Epoxy Grouting Material : A grouting material of high flexibility and adhesive strength for the racks of concrete structure, which recovers the staying power of the structure through perfect bonding and integration.

- Epoxy Sealing Material : A sealing material having an excellent adhesive strength with concrete metals, which seals the cracks to prevent the leakage of grouting material and helps set washer of syringe injector on the cracks.

Specification of Syringe Injector

-

Selection criteria based on the width and depth of cracks

Grouting material of low viscosity and long pot life should be used for the narrow but deep cracks while the grouting material of high viscosity and short pot life should be used for the side but shallow cracks. -

Selection criteria based on the injection device

You can use the grouting material of low viscosity for injection in low pressure with syringe injector, injection pot, reinjector etc and the grouting material of relatively high viscosity for the work with packer which can withstand high injection pressure. - For the repair of cracks of new structure with vibration or under stabilization process, you should use the grouting materials with elasticity and elongation. Some product of high strength may cause new cracks.

- The cracks of concrete structures usually contain moisture inside due to the difference in temperature between the inside and the outside and due to the moisture in the air. Therefore, you should use, even for the dried surface, such a type of resin that has high adhesive strength for wet area and should use wet type resin especially for the cracks of underground structures.

Specification of Reinjector

-

01. Inspection of cracks and surface treatment

- Work process should be determined by checking in advance the condition, width, depth of cracks.

Remove dust or dirt from the area to be sealed with a wire brush and remove dirt from the surface by using a detergent like soap or thinner if any oily substance still remains

- Work process should be determined by checking in advance the condition, width, depth of cracks.

-

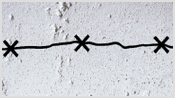

02. Determine the area where to place washer

- The washer should be placed in an interval of 15cm~20cm depending oh the width of cracks.

Usually 20cm is the most appropriate distance between the washers. You should put 5~6 washers for the repairing of cracks of one meter length.

- The washer should be placed in an interval of 15cm~20cm depending oh the width of cracks.

-

03. Sealing of cracks

- You should seal cracks with epoxy sealing material, 1mm think and 30mm wide, except for areas where to put the washer to prevent the injected epoxy from leaking, If sealing is not properly done on cracks, loss of epoxy resin can occur due to the damage of sealing when injection device is installed. Therefore, you should pay special attention while you work.

-

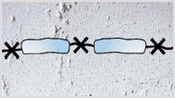

04. Setting the washer

- You should set the washer with epoxy sealing material on the places make in advance.

Stop the work until the sealing material is completely hardened. (It takes about 24 hours at the normal temperature of 25Ōäā)

- You should set the washer with epoxy sealing material on the places make in advance.

-

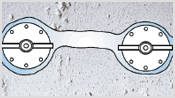

05. Injection of Epoxy

- Fill the syringe injector with 30cc of epoxy grouting material and connect rubber bands with the washers. Place all the syringe injectors on the washers in the same way.

when the grouting material of a syringe injector is consumed before tack free, you have to replace the syringe injector promptly with a syringe injector newly charge and continue injection.

- Fill the syringe injector with 30cc of epoxy grouting material and connect rubber bands with the washers. Place all the syringe injectors on the washers in the same way.

-

06. Finishing Work

- After confirming that the grouting material is hardened, remove the syringe injector and washer and grind the surface cleanly with a hand grinder and finish, if necessary, with crack cover material or paint, (You can do the finishing work after about one day in summer, and about two days in winter, which is required for initial hardening)

Notes on job site work

- Never fail to abide by the designated mixture ratio, for it is the dual component type of the main material and the hardener. Acceleration or deceleration of the hardening speed through a random increase or decrease of the hardener will cause greatly reduce the post hardening properties.

- Mix the volume only that you can use up within the pot life. Pay attention to the fact that the reaction speed of mixed resin becomes fast when the temperature is high or its volume is large, and slow when the temperature is low or its volume is small.

- If the temperature is below 5Ōäā at the site, raise the temperature by indirect heating before use.

- Please inject sufficient quantity of epoxy resin if there are too many air voids, or the base structure is not strong, or injection is made into cement block or the cracks are penetrated.(Some of epoxy resin should still remain in the injector even after the injection is completed)If the epoxy is absorbed into the base structure concrete or runs down, the inside of the cracks may still remain empty.

- Pay attention to the ventilation of the site and avoid long work. Be wary of fire while handling. Epoxy does not contain flammable organic solvents, but it is still flammable substance.

- Clean the tools, containers etc promptly when the work is finished.

- Please make sure that it does not come into contact with human skin directly. (use protective glove etc) If it happens to come into contact with your skin, wash it well with a large amount of water and soap. In case it gets into your eyes, wash it with water immediately and see a doctor.

Main Contents

-

Daehwa Precision

-

Mechanical injection packer

-

concrete crack injection repair

-

concrete repair kits

-

Single component Injection Pump

-

Twin Line Injection Pump

-

Acrylic Injection Pump

-

Grouting Injection Pump

-

grouting injection

-

polyurethane injection system

-

resin injection pump

-

repair of concrete

-

epoxy injections

-

epoxy injection system

-

epoxy injection systems

-

concrete repair epoxy injection

-

Water stop grouting Method

-

Reinjector Injection Method

-

Syringe Injection Method

-

concrete repair epoxy mortar