-

Grouting

Equipments -

- ļīĆĒÖöņĀĢļ░ĆĻ│ĄņŚģņØĆ ņĄ£Ļ│Ā ĒÆłņ¦łņØś ņ×Éņ×¼ļź╝ ņāØņé░ĒĢśĻĖ░ ņ£äĒĢ┤ ļģĖļĀźĒĢ®ļŗłļŗż.

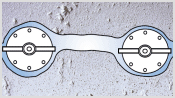

- Syringe Injector

Characteristics

- As the movement of injected resin is enlarged in concentric circles, no defect or separation is generated by the injection pressure.

- Made of transparent material, users easily observe the injection volume with Clear eyes.

- As it allows users to repair the structure cleanly while maintaining the original status and without dismantling or entering down, Is costs less repair expense and saves time for work.

- As injection is made by low pressure similar to the one generated by a rubber band, it causes less damage to the sealed area. And also to offers high work precision, construction management is make easier.

-

Specifications Specifications Capsule capacity 40cc Bench diameter ╬”49 Max.pressure 2.5kgf Max.length 210mm Min.length 145mm Weight 35,7g Surface adhesiveness 38kgf -

Specifications Specifications Capsule capacity 50cc Bench diameter ╬”49 Max.pressure 2.5kgf Max.length 250mm Min.length 160mm Weight 42,4g Surface adhesiveness 38kgf

Syringe injector Injection System

-

01. Surface cleaning

- Examine the crack status, width, depth, and others prior to deciding injection method.

-

02. Marking the bench positions

- If the concrete thickness is 200mm~300mm and the crack width is 1mm or less.

Five benches are required per meter in general. The required number of benches Depends on concrete thick ness and crack width, Decide and mark where to place the fixing Plates after checking the crack status.

- If the concrete thickness is 200mm~300mm and the crack width is 1mm or less.

-

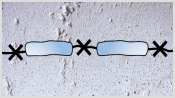

03. Attaching the benches

- Attach and fix the injection benches with epoxy sealing material. Make sure that sealing material is applied to the benches seamlessly.

-

04. Sealing

- Perform 1mm-thick, 30mm-wide epoxy sealing on the crack except the parts where he benches are placed. in an effort to prevent injection material from Overflowing the crack.

Verify that sealing material has hardened sufficiently.

- Perform 1mm-thick, 30mm-wide epoxy sealing on the crack except the parts where he benches are placed. in an effort to prevent injection material from Overflowing the crack.

-

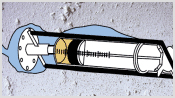

05. Injection

- Fill the injection material to cylinder body, insert it into the fixing plate, and then fix it with elastic cord or spring.

(To be noted, you need to replace the cylinder body with a recharged one if more than 30cc of injection is required.)

- Fill the injection material to cylinder body, insert it into the fixing plate, and then fix it with elastic cord or spring.

-

06. Finish

- Verify that injection material has hardened, Remove the fixing plates, and then perform surface processing with a hand-grinder.

Work photo

Main Contents

-

Daehwa Precision

-

Mechanical injection packer

-

concrete crack injection repair

-

concrete repair kits

-

Single component Injection Pump

-

Twin Line Injection Pump

-

Acrylic Injection Pump

-

Grouting Injection Pump

-

grouting injection

-

polyurethane injection system

-

resin injection pump

-

repair of concrete

-

epoxy injections

-

epoxy injection system

-

epoxy injection systems

-

concrete repair epoxy injection

-

Water stop grouting Method

-

Reinjector Injection Method

-

Syringe Injection Method

-

concrete repair epoxy mortar