-

- ыэь ыАъГЕь ь ьЕъГ эьЇь ььЌыЅМ ььАэъИА ьэД ы Иы ЅэЉыыЄ.

- Epoxy Sealant

- Goods View

- DH-400S Dry Type Sealant DH-400WS Wet Type Sealant DH-700 Elastic Type Sealant(Elongation50%) DH-207 High Viscosity Sealant DH-130S Fast hardening Sealant DH-207F High Viscosity & Elasticity Sealant DH-600 Elastic Sealant(Elongation 20%)

-

Epoxy Sealant

DH-207 High Viscosity Sealant

- Price

- inquiry

- Feature & Purpose

- DH-207 is make from Epoxy Resin with Polyamide for high viscosity sealant

- attached file

- attached file2

DH-207 high viscosity sealing material is a product developed and made with epoxy resin and polyamide as main ingredients. This grease type putty is developed for areas where sealing mark should not be left after sealing and easily used for concrete cracks or rough walls where no deep infiltration is necessary. This product's excellent quality shows better mechanical strength once stiffened than epoxy injection pumps. The excellent adhesive strength of epoxy resin ensures that the hardened composition maintains a sufficient adhesive strength for the cement mortar, concrete and reinforcing bar etc. and does not produce de-lamination from the base member of the structure.

The excellent adhesive strength of epoxy resin ensures that the hardened composition maintains a sufficient adhesive strength for the cement mortar, concrete and reinforcing bar etc. and does not produce de-lamination from the base member of the structure. If a crack of vertical structure is filled with the high-purity mayonnaise-chemistry putty having thixotropy, the resin does not flow down.

If a crack of vertical structure is filled with the high-purity mayonnaise-chemistry putty having thixotropy, the resin does not flow down. It, as a pure epoxy resin without any filler, provides a good self-leveling and transparent sealing part, making it easy to do finishing task.

It, as a pure epoxy resin without any filler, provides a good self-leveling and transparent sealing part, making it easy to do finishing task. It features a low hardening speed, meaning that it makes it easy to work and there is no shrinkage. It can be used at various areas, including filling of large crack part, high strength sealing of V cutting part, and using as an anchor volt binder of wall and ceiling surfaces.

It features a low hardening speed, meaning that it makes it easy to work and there is no shrinkage. It can be used at various areas, including filling of large crack part, high strength sealing of V cutting part, and using as an anchor volt binder of wall and ceiling surfaces. Compared to cement mortar or concrete, it has superior mechanical strength in all respects Including compressive strength, bending strength and tensile strength etc.

Compared to cement mortar or concrete, it has superior mechanical strength in all respects Including compressive strength, bending strength and tensile strength etc. Sealing of cracked area for crack repairing, for setting washer and sealing for the reinforcement of steel plate.It is used for the repairing of cracks of over 3mm when the measured width of a crack is larger than the allowable width in case the target member is structural member, or when the structural stability, durability, waterproof should be considered regardless of the identity of the target member. Applications are as follows.

Sealing of cracked area for crack repairing, for setting washer and sealing for the reinforcement of steel plate.It is used for the repairing of cracks of over 3mm when the measured width of a crack is larger than the allowable width in case the target member is structural member, or when the structural stability, durability, waterproof should be considered regardless of the identity of the target member. Applications are as follows.

Filling of large cracks of exterior wall of masonry structure.

Filling of large cracks of exterior wall of masonry structure. Filling after V-cutting or U-cutting of large cracks of exterior wall of concrete structure.

Filling after V-cutting or U-cutting of large cracks of exterior wall of concrete structure. Filling after V-cutting or U-cutting of the floor of underground parking lot.

Filling after V-cutting or U-cutting of the floor of underground parking lot. Sealant filling of large building.

Sealant filling of large building. Filling of joints of concrete structures.

Filling of joints of concrete structures. Grouting reinforcement of aged, weakened parts of concrete.

Grouting reinforcement of aged, weakened parts of concrete.DH-207 Dimension Details DH-207 Dimension Details Classification Main Component Hardening Component Remarks Exterior Appearance White Paste Yellow Paste - Mixing Rate 2 1 - Specific Gravity 1.14 ± 0.1 0.99 ± 0.1 23±0.5т Pot Life(Min) 60±10 23±0.5т Tack Free Time(Hours) 14±5 23±0.5т Hardening Time(Hours) 24 ~ 36 - Packing Unit 10kg 5kg - DH-207 Property Data DH-207 Property Data Test Category Result Value Base Value Test Method Compression Strength ( N/у ) 105 50 over KS F 4923 Adhesive Strength ( N/у ) 10.3 6 over Seal Breaking Expansion Rate ( % ) 2.2 10 under Seal Strength ( N/у ) 47.4 15 over Hardening Contraction Rate ( % ) 0.9 3 under Heating Change (110±3т,168hr) eight Change Rate ( % ) 1.2 5 under Volume Change Rate ( % ) 0.4 5 under

Pot Life The period of time during which you can work without a change in viscosity after resin and hardener are mixed.

Pot Life The period of time during which you can work without a change in viscosity after resin and hardener are mixed. Tack Free the state of hardening in which you can lightly touch the mixed resin with your hand, But the hardened material does not stick.

Tack Free the state of hardening in which you can lightly touch the mixed resin with your hand, But the hardened material does not stick. Hardening Time the time it takes for the mixed resin to be hardened enough to realize about 80% of final mechanical strength.

Hardening Time the time it takes for the mixed resin to be hardened enough to realize about 80% of final mechanical strength.

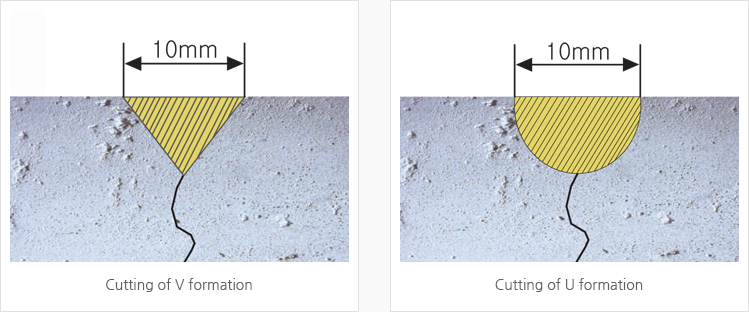

As shown above, V-cutting and U-cutting is applicable to the repairing of relatively wide cracks over 0.5mm. The following work guidelines describe how to do a filling after cutting. The ways are subject to change depending upon the site condition.

Limitations on the work Work shall not be allowed when the ambient temperature of the job site goes out of the range of 5т~30т or the humidity is over 85%. Work is not allowed for the area where concrete is wet or set with more than 10% moisture in it or polymerized. To prevent the condensation of moisture, the surface temperature of surface temperature must be higher than the dew point at least by 3тE and the relative humidity shall be lower than 85%.

Limitations on the work Work shall not be allowed when the ambient temperature of the job site goes out of the range of 5т~30т or the humidity is over 85%. Work is not allowed for the area where concrete is wet or set with more than 10% moisture in it or polymerized. To prevent the condensation of moisture, the surface temperature of surface temperature must be higher than the dew point at least by 3тE and the relative humidity shall be lower than 85%. Inspection of cracks and treatment of surface

Inspection of cracks and treatment of surfaceWork process shall be determined by checking in advance the condition, width, depth of cracks. Remove dust or dirt from the area to be sealed with a wire brush and remove dirt from the surface by using a detergent like soap or thinner if any oily substance still remains. By using gas burner, if needed, dry the inside of cracks as much as possible before you start sealing so that you can remove moss or excessive moisture from the inside or surroundings of cracks.  V-cutting or U-cutting of cracks

V-cutting or U-cutting of cracksMake V-cutting or U-cutting of cracks in the width of about 10mm with a 4-inch grinder. When you make a U-shape cut, you have to cut the structure along the both side of cracks with a cutter and take off the concrete in-between.  Cleaning of cracks

Cleaning of cracksBlow out completely dust or foreign matters from the inside of cracks with an air compressor.  Mixing of Epoxy Resin

Mixing of Epoxy ResinMix DH-207 High viscosity sealing material in the ratio of 1:1 in accordance with the designated formula (based on weight). You have to mix properly based on the weight and can use steel scoop for mixing the main material and the hardener to produce a uniform color. (Special attention should be paid to the mixing work, because poor mixture or poor mixing formula can lead to non-hardening)  Filling with Epoxy Resin

Filling with Epoxy ResinFill the V-cutting or U-cutting cracks with DH-207 High viscosity sealing material by using a rubber scoop. Please use up all the mixed epoxy resin within it pot life. When 24 hours or so have elapsed, fill with or apply high viscosity sealing material once again with a scoop. The second time application of High viscosity sealing material will give extra coverage on the rough surface or those areas that are contracted or omitted during the initial application.  Finishing work

Finishing workPlease harden at least 24~36 hours after the filling. Do the finishing by sealing with crack cover material (DH-CF30), if necessary, and painting. All the equipments and tools that are used for this operation should be cleaned when the operation is finished. Detergent such as M.E.K, Acetone, Xylene, Toluene and epoxy thinner should be used when cleaning. If the Foam is smeared on your skin during the performance, wash it immediately with flowing water.- When you treating medical fluid, make sure you wear protective helmet, goggle clothes and other protective devices.

- If the medical fluid is smeared on your skin, wash it off immediately and clean up with soapy water.

- All the hand tools and equipments that are used for this operation should be cleaned with thinner thoroughly.

- If you are working in sealed room, then make sure to conduct constraint ventilation for clean air.

- If the medical fluid is smeared on your skin and causes skin trouble, then you should go see specialist for prescription.

- If the temperature is below 5т, then you must artificially raise up the temperature of medical fluid. This way you can get proper Pot Life.

- If the atmosphere temperature is high and the area is humid, Pot Life of medical fluid quickens. On the contrary, Pot Life will slow down in low temperature area.

- Be aware of it before you conduct the operation.Recommended temperature for storage is 10~25т with no moisture. Store it in cool area. Storing period is about 6 months in sealed condition however it can be corrupted according to storing area and conditions. Preferably use it as soon as possible.

Main Contents

-

Daehwa Precision

-

Mechanical injection packer

-

concrete crack injection repair

-

concrete repair kits

-

Single component Injection Pump

-

Twin Line Injection Pump

-

Acrylic Injection Pump

-

Grouting Injection Pump

-

grouting injection

-

polyurethane injection system

-

resin injection pump

-

repair of concrete

-

epoxy injections

-

epoxy injection system

-

epoxy injection systems

-

concrete repair epoxy injection

-

Water stop grouting Method

-

Reinjector Injection Method

-

Syringe Injection Method

-

concrete repair epoxy mortar